This provides management with a better view of the detailed activities involved (purchasing materials, machine setups, inspections, and so forth) and the cost of each activity. Managers are more likely to focus on improving efficiency in the most costly activities, thereby reducing costs. This $4 per DLH rate would then be used to apply overhead to production in the accounting period. The difference between actual and applied overhead is later assessed to determine over- or under-application of overhead. We’ll outline the basic formulas used to calculate different types of overhead rates and provide overhead cost examples. So in summary, the overhead rate formula relates your indirect operating costs to production costs.

Predetermined Overhead Rate Calculation (Step by Step)

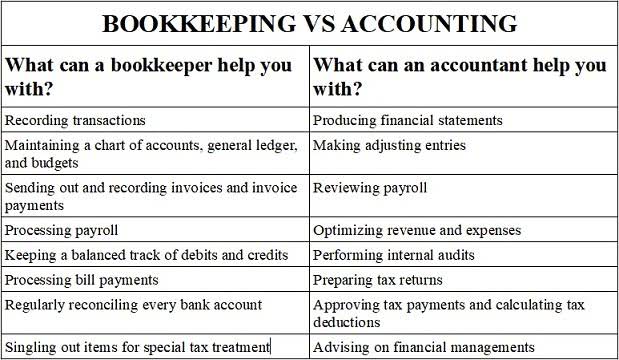

The companies that used activity-based Online Bookkeeping costing (ABC) had higher overhead costs as a percent of total product costs than companies that used traditional costing. The complexity of production processes and products tended to be higher for those using ABC, and ABC companies operated at capacity more frequently. This $4 per hour overhead rate would then be applied to the number of direct labor hours for each job to allocate overhead costs. Divide the total manufacturing overhead cost by the estimated total units of activity to determine the predetermined overhead rate. Predetermined overhead rates are used to assign overhead costs to products or services, enabling accurate product costing and pricing. Product costing involves allocating costs from activity centers to products and calculating a product cost per unit.

Product Costs Using the Activity-Based Costing Approach at SailRite

Commonly, the manufacturing overhead cost for machine hours can be ascertained from the predetermined overhead rate in the manufacturing industry. Further, it is stated that the reason for the same is that overhead is based on estimations and not the actuals. In a standard cost system, accountants apply fixed manufacturing overhead to the goods produced using a standard overhead rate. They set the rate prior to the start of the period by dividing the budgeted manufacturing overhead cost by a standard level of activity (called the base).

4: Using Activity-Based Costing to Allocate Overhead Costs (Part

This rate is calculated by dividing the total estimated overhead costs for the period by the total estimated activity base for all production departments combined. This is done by dividing the estimated overhead petty cash costs (from step 2) by the estimated level of cost driver activity (from step 3). Figure 3.4 “Predetermined Overhead Rates for SailRite Company” provides the overhead rate calculations for SailRite Company based on the information shown in the previous three steps. Until now, you have learned to apply overhead to production based on a predetermined overhead rate typically using an activity base.

- The problem with this approach is that fixed costs are often a large part of the overhead costs being allocated (e.g., building and machinery depreciation and supervisor salaries).

- In contrast, the traditional allocation method commonly uses cost drivers, such as direct labor or machine hours, as the single activity.

- This rate would then charge $4 of overhead to production for every direct labor hour worked.

- The management can estimate its overhead costs to be $7,500 and include them in the total bid price.

It allows overhead to be assigned to production based on activity (DLHs), providing insight into profitability across products. Accurately calculating overhead rates is important for determining the full cost of a product and appropriately pricing goods and services. If overhead costs rise rapidly, increasing overhead rates will make this clear. In this step, overhead costs are assigned to each of the activities to become a cost pool. A cost pool is a list of costs incurred when related activities are performed.

Companies that use activity-based costing, such as Hewlett Packard and IBM, may identify hundreds of activities required to make their products. The most challenging part of this step is narrowing down the activities to those that have the biggest impact on overhead costs. Figure 9.1 illustrates how the costs in each pool are allocated to each product in a different proportion.

- Understanding how to calculate this rate empowers businesses with the ability to make informed decisions, optimize pricing strategies, and enhance profitability.

- As you can see in Figure 3.6, overhead is a significantcomponent of total product costs.

- Whereas, the activity base used for the predetermined overhead rate calculation is usually machine hours, direct labor hours, or direct labor costs.

- The sales price, cost of each product, and resulting gross profit are shown in Figure 6.6.

Computing Actual Overhead Costs

Based on the above information, we must calculate the predetermined overhead rate for both companies to determine which company has more chance of winning the auction. The total manufacturing overhead cost will be variable overhead, and fixed overhead, which is the sum of 145,000 + 420,000 equals 565,000 total manufacturing overhead. Most businesses recalculate their rate annually as part of their budgeting process. However, if you experience significant changes in your operations or costs, you might want to recalculate mid-year.

- Sales of each product have been strong, and the total gross profit for each product is shown in Figure 6.7.

- It can help manufacturers know when to review their spending more closely, in order to protect their business’s profit margins.

- This information is needed to calculate the product cost for each unit of product, which we discuss next.

- The sales price was set after management reviewed the product cost with traditional allocation along with other factors such as competition and product demand.

- Direct labor hours measure the amount of time workers spend performing tasks directly related to producing goods or services.

- Various tools help in calculating and applying predetermined overhead rates effectively.

- In larger companies, each department in which different production processes take place usually computes its own predetermined overhead rate.

However, any activity that is a good measure of the consumption of overhead costs can be used. The traditional method involves dividing the total estimated overhead costs by the total estimated activity base for a given period. This is a straightforward approach but can be less accurate if the overhead costs and activity levels do not have a consistent relationship or if the estimates are not reliable. Since overhead costs cannot be easily traced to individual products like direct material or labor costs, overhead rates help to allocate a fair share of these costs based on the activity of making the product.

Hence, this predetermined overhead rate of 66.47 shall be applied to the pricing of predetermined overhead rate formula the new product VXM. In this guide, we’ll walk through a step-by-step process for calculating the predetermined overhead rate, its importance, and best practices for accuracy. This information is needed to calculate the product cost for each unit of product, which we discuss next. Notice that this information includes an estimate of the level of activity for each cost driver, which is needed to calculate a predetermined rate for each activity in step 4.